Characteristics and application of silicone foam materials in new energy vehicles

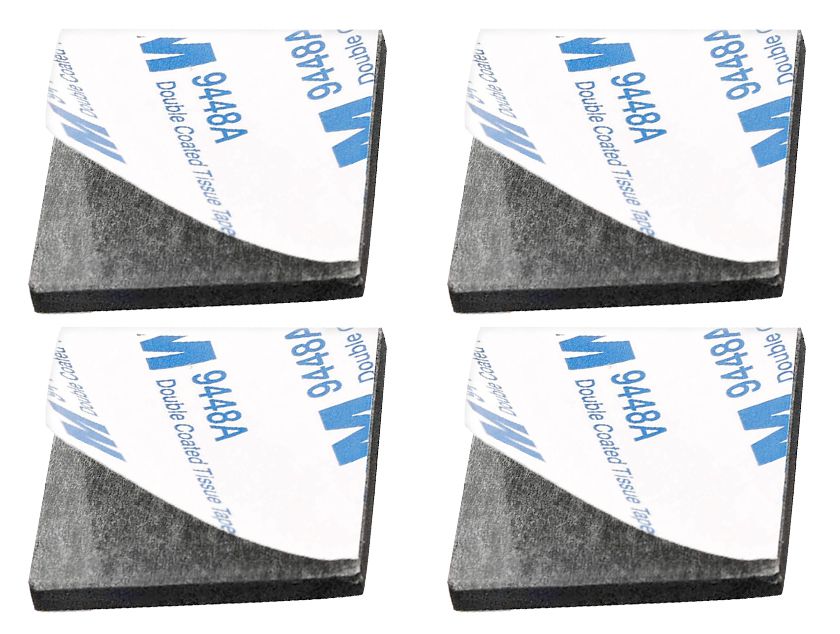

Silicone foam material (also known as: silicone foam/foamed silica gel) is a kind of porous, low Density, compressible polymeric elastomer material. Nowadays, silicone rubber foam is widely used because it has the excellent properties of both silicone rubber and foam materials. Silicone foam has the high elasticity of rubber, and also has the properties of sound absorption and sound insulation, shock absorption and buffering that foam materials have, and is mostly used for shock absorption pads, gaskets, sound insulation materials, insulation materials, aviation insulation materials and other materials. occasions with high performance requirements.

Characteristics of silicone foam material (foamed silicone)

Silicone foam is increasingly widely used, because it has the excellent properties of silicone rubber and foam materials at the same time, not only has the high resilience and aging resistance of rubber, but also has the properties of sound absorption, shock absorption and other foam. It is suitable for situations with relatively high performance requirements such as waterproof, shock absorption, gasket (sealing grade IP68), sound insulation, insulation, and aviation heat insulation. According to the cell structure, silicone foam is divided into three types: closed cell type, open cell type and mixed type.

The closed-cell foamed silicone foam material has the characteristics of good shockproof buffer, sound insulation, heat insulation, flame retardant and explosion-proof. Foamed silicone gaskets for energy vehicle batteries, etc.

Many interior materials of today's automobiles, such as floors, ceilings, steering wheels, and car seats, are all polyurethane foam materials. Because the price of polyurethane foam material is lower. However, polyurethane-based foam materials have poor weather resistance, are flammable, and release a large amount of toxic gases that are harmful to the human body during combustion. Therefore, with the promotion of silicone foam materials and the improvement of people's understanding of them, silicone foam materials are expected to replace traditional polyurethane foam materials in the future.

Density selection of silicone foam

The density of the silicone foam matrix is 1.17g/cm3. However, through foaming treatment, the density of the silicone foam material prepared in the current mature process can be as low as 0.16-0.20 g/cm3, which can be used for parts such as car seats and headrests; while the conventional silicone rubber foam The material (density of 0.45 g/cm3) is widely used for gap filling in sealing, shock absorption and other parts.

Flame Retardant Properties of Silicone Foam

According to scientific experimental research data, silicone foam added with flame retardant has good flame retardant properties. The flame retardant grade can reach UL94-V0, which can be used in electric vehicles to reduce the problems caused by combustion.

Electrical insulating properties of silicone foam

With the increase of the amount of physical filler, the volume resistivity and surface resistivity of silicone rubber tend to decrease, and the dielectric constant and dielectric loss factor generally tend to increase. It can be seen that the addition of physical fillers impairs the electrical insulating properties of silicone rubber to a certain extent.

Application of Silicone Foam Materials in New Energy Vehicles

The technical key of new energy electric vehicles lies in the charging and discharging technology and safety performance of high-energy-density lithium batteries of electric vehicles. Lithium batteries must maintain strict waterproof and dustproof requirements during use, and easy to heat and spontaneous combustion is the first problem that affects the safe use of electric vehicles. Under extreme conditions such as heavy rain, shoal, and haze, in order to meet the requirements of sealing and buffering protection of power batteries during vehicle driving, silicone foam materials can be applied to power batteries. Use silicone foam potting material to protect individual cells. Silicone foam materials are also used in power battery packs.

Silicone foam is also widely used for anti-leakage, dust-proof, shock-absorbing, and air-tightness treatments around headlights; as well as anti-noise and gap-filling treatments around electric car horns and speakers.